In winter 2012, SRI International began building a proof-of-concept system to demonstrate natural gas storage at low pressure in a conformable tank. We featured the technology, funded under the Advanced Research Projects Agency—Energy (ARPA-E) Methane Opportunities for Vehicular Energy (MOVE) program, at ARPA-E’s 2013 Energy Innovation Summit.We returned to the 2014 Summit this week to report that we’ve met our milestones and are wrapping up the project.

In some arenas, successful completion of a project means the opportunity to pursue more research funding. At SRI, we define innovation as the creation and delivery of new customer value into the marketplace with a sustainable business model for the enterprise producing it. We look forward to licensing the natural gas storage technology to a company that will continue the technology’s development with commercial applications in mind.

SRI’s MOVE project showed a pathway to conformable natural gas storage tanks that can be incorporated into unused space in automobiles, allowing designers to integrate the tanks into vehicle designs without sacrificing passenger or trunk space.

These tanks will be safer than conventional natural gas tanks because they store the natural gas at low pressure, about 500 psi, in a solid carbon sorbent made by ATMI, Inc. For comparison, 500 psi is closer to the 100 psi that many bicycle tires require than the 3,000 to 3,600 psi used for most compressed natural gas (CNG) tanks. The carbon holds about the same amount of natural gas as a CNG tank, but if there is sudden, unexpected damage to the tank, the carbon will slowly release the natural gas through diffusion. Low pressure could also enable refueling at homes that already use natural gas for applications such as heating and cooking.

Titanium Metal and Alloy Production

What’s next in our energy innovation pipeline? With funding from ARPA-E’s Modern Electro/Thermochemical Advances in Light Metals Systems (METALS) program, SRI is starting a new project to develop a process that could reduce the cost, energy consumption, and carbon dioxide emissions associated with titanium metal and alloy production.

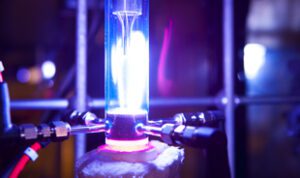

SRI’s new approach to titanium or titanium alloy production uses a proprietary multi-arc fluidized bed reactor (MAFBR) that will either convert titanium tetrachloride to titanium powder or convert multiple metal chlorides to titanium alloy powder in a single step. The process will enable production of alloys that cannot be produced with conventional technology, at a cost similar to stainless steel.

Until now, powder metallurgy—the process of blending fine powdered materials, pressing them into a desired shape or form, and then heating the compressed material to bond the material—has not been practical with titanium because of the high cost of producing powders derived from ingots.

SRI is solving that problem by developing a multi-arc fluidized bed reactor (MAFBR) that will be able to either convert titanium tetrachloride to titanium powder or convert multiple metal chlorides to titanium alloy powder in a single step. The process will enable production of alloys that cannot be produced with conventional technology, at a cost similar to stainless steel.

Direct powder production eliminates costly, energy-intensive steps to produce sponge and ingot, as well as the waste associated with machining parts from metal. Producing titanium alloys at a cost similar to stainless steel could make titanium a cost-competitive option for use in lightweight vehicles with improved fuel efficiency.

The information, data, or work presented herein was funded in part by the Advanced Research Projects Agency-Energy (ARPA-E), U.S. Department of Energy, under Award Numbers DE-AR0000460 and DE-AR0000250.

The information, data, or work presented herein was funded in part by an agency of the United States Government. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.

Visit SRI at booth # 524 at the ARPA-E Energy Innovation Summit to learn more about our projects and energy innovation pipeline.