XDR溶接可視化技術により実現した溶接部の広範な3D視野とスマートヘルメットで収集するデータとを駆使し、新しい技能者を育成

課題と目的

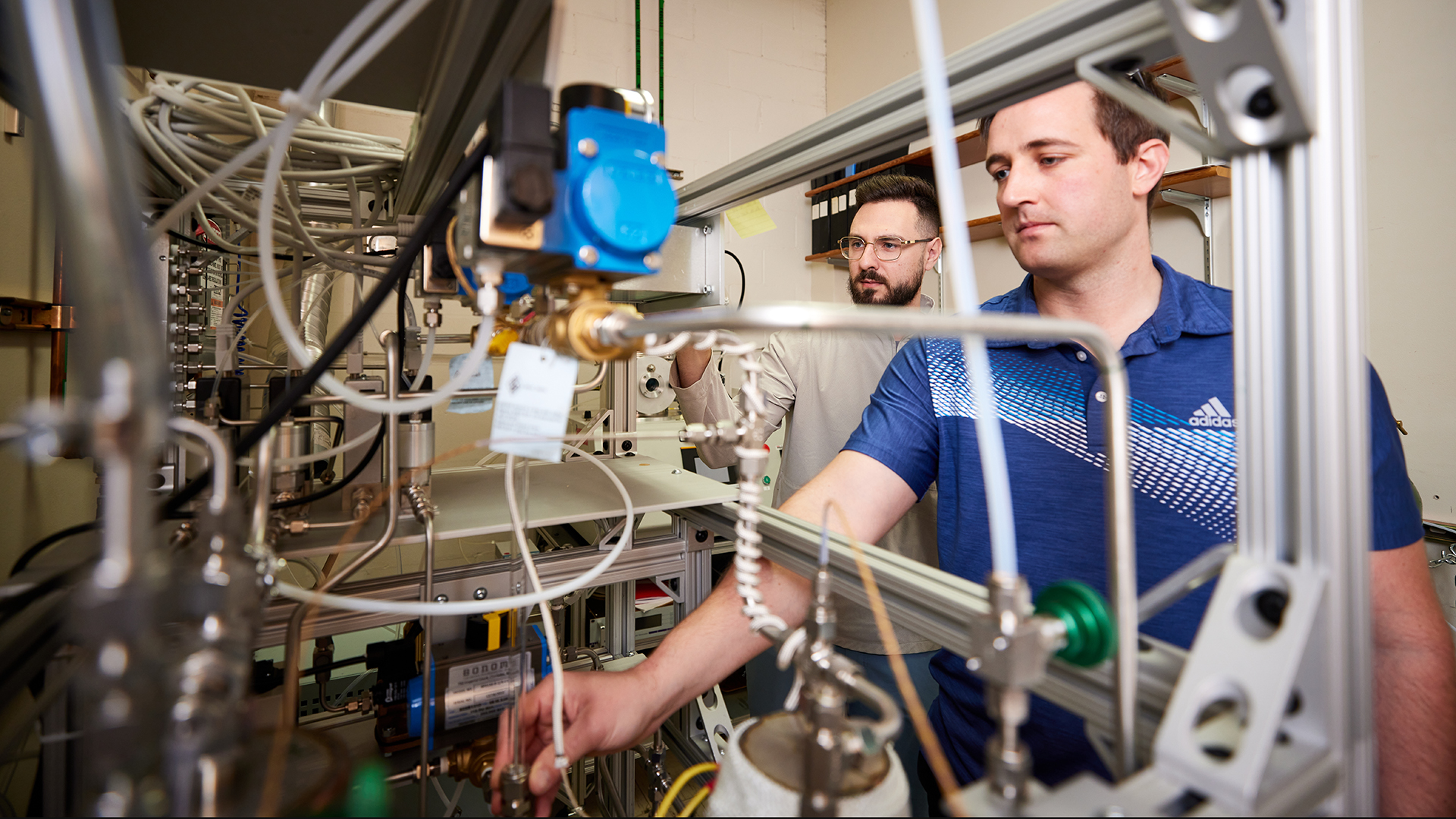

既存の溶接用面で使用されている遮光フィルターは視認性と生産性とを犠牲にし、溶接技能者の目を保護してきました。そのため、従来労働力不足という課題に直面する日本の建設業界において、溶接技能者が高度な技術を身につけるまでには長い年月がかかりました。そこで川田テクノロジーズはSRIに依頼し、生産性を改善して安全性を高める、若年世代の溶接技能者育成を担う新しい溶接ヘルメットの製作に着手しました。

ソリューションと成果

SRIでは画像処理を応用した3D溶接ヘルメットを開発し、アーク溶接の際に何も遮られることなく溶接部全体の視野を技能者が得られるようにしました。新しい拡張ダイナミックレンジを用いた溶接可視化技術(XDR)によって、技能者はより効率的で正確な溶接を行うことができ、新しい技能者にも数年の経験に相当する技術習熟が可能となります。

川田グループの川田工業株式会社は日本の建設・橋梁事業大手で、アーク溶接で接合した鋼製厚板部材の製作を多数手がけています。KTI川田グループとSRIが連携することで、新しい技能者を訓練し、これまでの業務で蓄積した溶接技術を次に伝えるために要する時間を大幅に短縮する新技術の開発に至りました。

SRIでは先端視覚技術を応用し、XDR溶接可視化技術を開発しました。これは、小型のカメラモジュールと画像融合技術を使用し、ステレオビジョンまたは3D画像としてXDR合成画像を表示するものです。この新しい3D溶接ヘルメットは従来の溶接面に比べて視野が格段に広がり、実務経験の少ない溶接技能者であっても容易に有用な情報を収集・確認することで、高品質の溶接を行うことができます。またXDRでは溶接技能者の目線画像を記録できるため、今後データを解析することで一人一人の溶接技能者や新規の技能者の学習曲線の加速につながります。

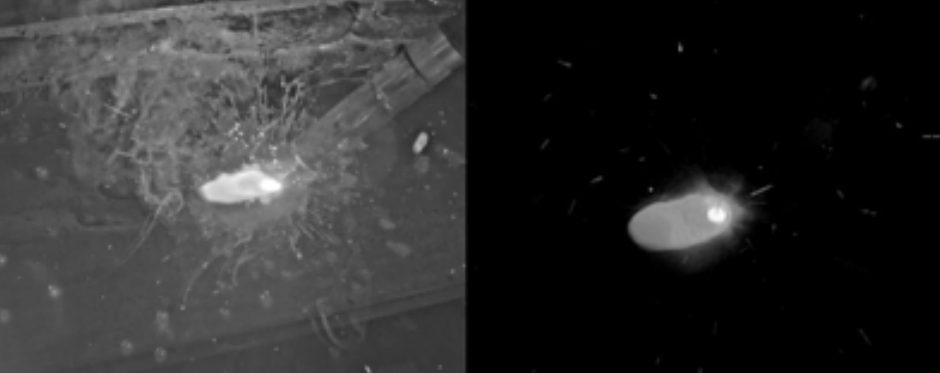

XDRはシャッタースピードと撮影時間を制御し、1/1000秒単位で画像が記録されます。また同じ画角で異なる露出条件の画像を取得するため、画像が露出アンダーや露出オーバーになることはありません。記録した複数のフレームはGPUで処理し、リアルタイムで一つのフレームに合成します。

以下の写真は、XDR(左)と従来の溶接面(右)の見え方を比較したものです。

3D溶接ヘルメットが溶接技能者の視野と視認性を格段に向上させることで、技能者はより確実に溶接を行えるようになりました。また溶接に関するさまざまなパラメータを表示し保存する機能も備えているため、有益な情報を容易に収集・確認できるようになり、特に実務経験の少ない溶接技能者には有効なものといえるでしょう。

川田グループでは今後もこの3D溶接ヘルメットの改良に取り組み、熟練の溶接技術の伝達へと活用させていきます。またヘルメットで得られたデータの解析も進めており、新規の技術開発及び製品開発の後押し、そして溶接全体の品質と信頼性の向上に取り組んでいます。