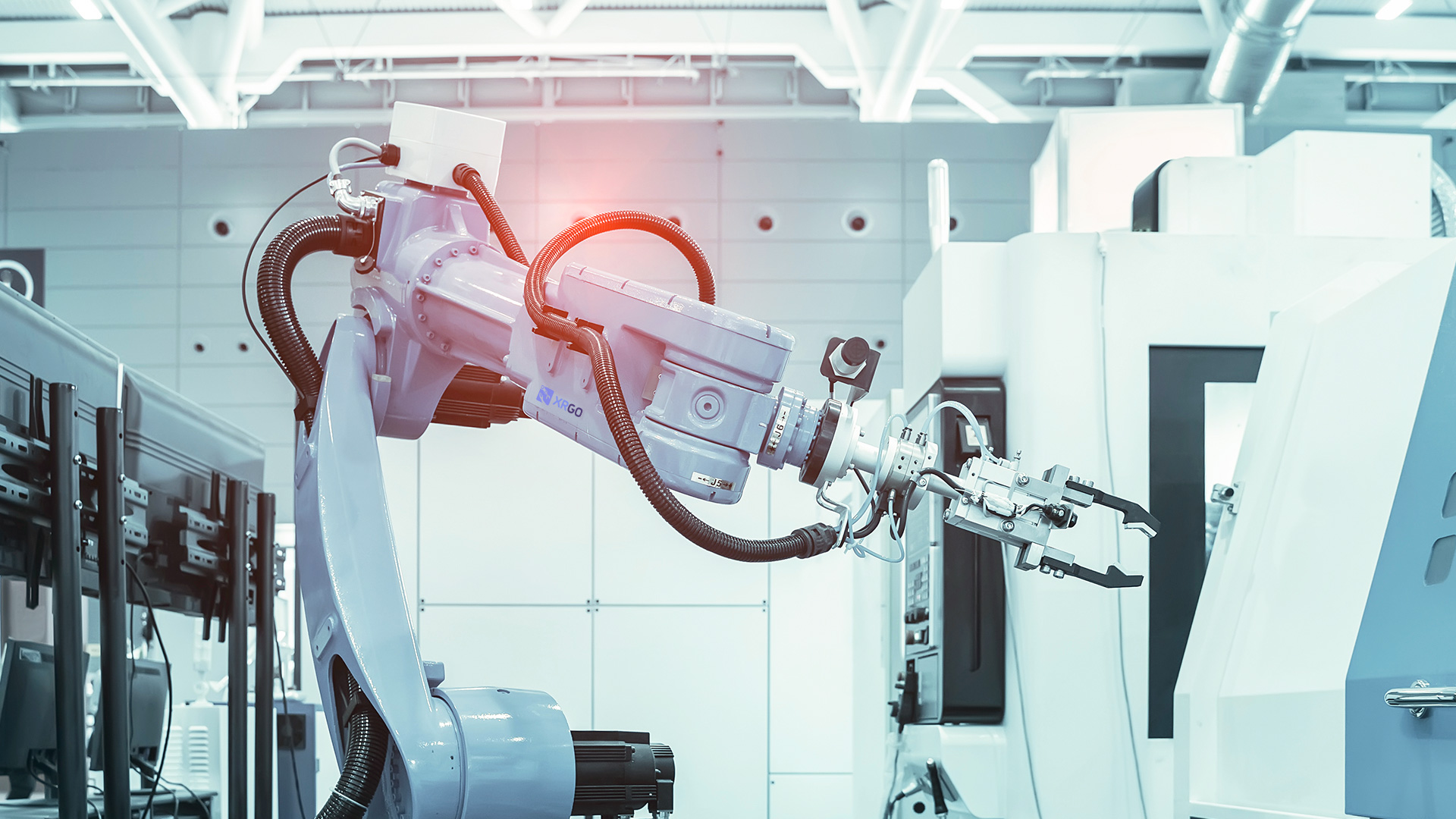

SRI International’s XRGo telemanipulation software was created to allow today’s industrial robot arms to be easily integrated, powering a wide variety of telemanipulation solutions.

The system provides a highly immersive augmented reality user experience that allows individuals to see in stereo (3D) as if they were right next to the robot arms.

What’s behind SRI’s XRGo telemanipulation software

Designed for integration with off-the-shelf industrial robot arms powering a wide variety of telemanipulation solutions.

High dexterity

Operate at various scales, from precise—threading a needle, to large—operating large equipment.

An immersive, intuitive user interface

Immersive 3D viewing that transports users to the task. Intuitive man-machine interface with proprioceptive operation. Haptic feedback for a variety of integrations, such as off-the-shelf virtual-reality headsets.

Flexible

Remote manipulation of complex tasks. Designed to be used with third party robot arms. Interchangeable tools offer flexibility with a wide variety of tasks. Scalable robotic arms move as the operators do.

Data recording

Capture the task during the operation—the robot’s arms, hands, tools, forces applied, and video of the operation as the operator sees them.

Integrated VR training

Use 3D models for easy training and operational planning without having physical models.

Maximize accuracy and efficiency with SRI’s XRGo intuitive AR system

Surgery

SRI’s XRGo telemanipulation software was the foundation of the first robotic surgeon, Da Vinci, the leading surgical robot system from SRI venture spin-off, Intuitive Surgical.

Pharmaceutical manufacturing

The need to repair or maintain equipment while pharmaceuticals are manufactured is common and requires a person to work inside the sterile manufacturing environment. Contaminants, changes to or hazards in the environment, and shutting down clean rooms are common issues that dramatically impact production.

SRI’s telemanipulation system for remote operation of the robot seeks to reduce downtime to production or impact to a sterile work environment.

Learn more about how SRI’s XRGo robotic platform could keep pharmaceutical cleanrooms sterile or telemanipulation in sterile environments.

Bomb disposal

The XRGo software is used by several organizations for bomb disposal. The ability to remotely disable a bomb has several advantages.

Energy

The energy sector has a mandate to minimize putting workers in hazardous environments. Telemanipulation can provide a solution. XRGo software can be applied to closed vessel maintenance and repair, hazardous or high-risk environments like mining, and high repairs and maintenance that require building a scaffold or using a crane.

Food processing

Impacts on labor, operations and logistics, and food processing are constant. The use of telemanipulation can fill gaps in the chain, so more impactful positions and operations can be prioritized.

Logistics

SRI’s XRGo software can be used to supplement heavy equipment such as construction equipment and forklifts.

Telemanipulation can help expand the workforce to include individuals who do not have the physical requirements to do the job on-site. As the technology expands, workers can perform their work remotely in different geographies, expanding the overall size of the potential workforce.

Get up and running

SRI’s telemanipulation software is being integrated with 3rd party robot arms so that pharmaceutical companies can test a number of use cases and proof-of-concepts. To find out how SRI’s system can help solve your big challenges that require telemanipulation.