Citation

L. Moro et al., “Low-cost solar-grade silicon: Purification and consolidation of silicon fines from wafering,” 2010 35th IEEE Photovoltaic Specialists Conference, Honolulu, HI, USA, 2010, pp. 003540-003545, doi: 10.1109/PVSC.2010.5614207.

Abstract

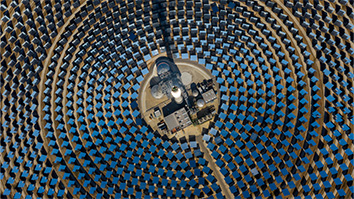

More than 90% of commercial solar cells are produced using mono- and poly-crystalline silicon, with estimated about 15,000 MT of silicon feedstock used in 2008. Future silicon use is estimated to grow proportionally with the solar industry (30%/y). Substantial amounts of highly refined polycrystalline silicon material are wasted in the final stages of producing ingots and in wafer slicing. Recycling of wasted silicon in the form of fines generated in deposition reactors and in slicing operation can lower the production cost of solar-grade silicon feedstock to less than $10/kg, and substantially shorten energy payback time. The SRI International developed technology is based on the prepurification and simultaneous melt-consolidation and further purification of silicon fines from wafering operations. The consolidated product in form of granules and ingots with a resistivity range of 1 to 5 Ω·cm can be used in the melt growth of both single-crystal and polysilicon ingots for use in photovoltaic cells.

Keywords: Silicon, Purification, Gallium, Silicon carbide, Artificial intelligence, Iron, Nickel