Using augmented reality and mobile technology to reduce construction overhead

CHALLENGE AND GOAL

Current construction practices are extremely tedious as inspection at every step must be manually performed and documented in order to ensure the structural integrity of buildings. It is a time-intensive process where errors can be costly in more ways than one. The goal of this project was to develop a tool that can aid inspectors in their process and collect more detailed information on the structures being built.

SOLUTION AND OUTCOME

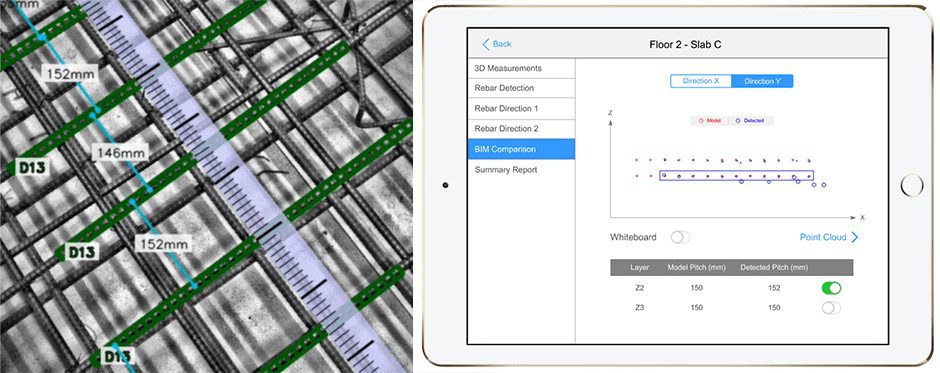

SRI International worked with Obayashi Corporation to develop an augmented reality (AR) system that could capture 3D information of built rebar and digitally tie this to 3D Building Models for easy searchability. The system captures the diameter, count, and pitch of rebar in each section, and identifies any discrepancies between as-built structures and the building plan.

The construction industry has long been plagued with manual processes that have been difficult to automate. Obayashi Corporation, a top Japanese construction firm, challenges this paradigm by funding multiple research and development (R&D) initiatives with aims to drastically modernize the industry.

Together with Obayashi, SRI developed a rebar inspection system that enables a single user to capture all the required building information while carrying just a tablet equipped with sensors, and a sensor package mounted to the helmet. By using complex vision technology and deep learning, the system uses simple cameras to precisely locate the user in the digital model, take relevant inspection metrics, and compare results to the original building plan. By developing such a tool, Obayashi hopes to introduce great efficiencies in rebar inspection while decreasing occurrences of costly mistakes.

One opportunity they identified was to improve the manual inspection process, which is a time-consuming yet critical task for quality control and assurance. This is typically a two-person task where the inspectors need to be reasonably well-trained to understand the structural complexities of buildings. Documentation is taken by filling out a digital form and taking photos using a digital camera with large rulers held next to the rebar