A novel manufacturing approach aims to scale these special materials for new industry applications.

Ceramic matrix composites (CMCs) are ceramic materials that take advantage of the reinforcing properties of small ceramic fibers embedded in a ceramic matrix. They are remarkably durable and heat-resistant when compared to standard ceramics.

Developed for applications like space vehicle re-entry — where resistance to thermal shock is highly desirable — they are also showing promise in other industrial applications where durability and temperature tolerance is at a premium, such as gas turbine engines and disk brakes.

If these materials have one Achilles heel, it’s cost: They remain quite expensive to produce. But as CompositesWorld reports, an SRI team is laying the groundwork for more cost-effective CMCs.

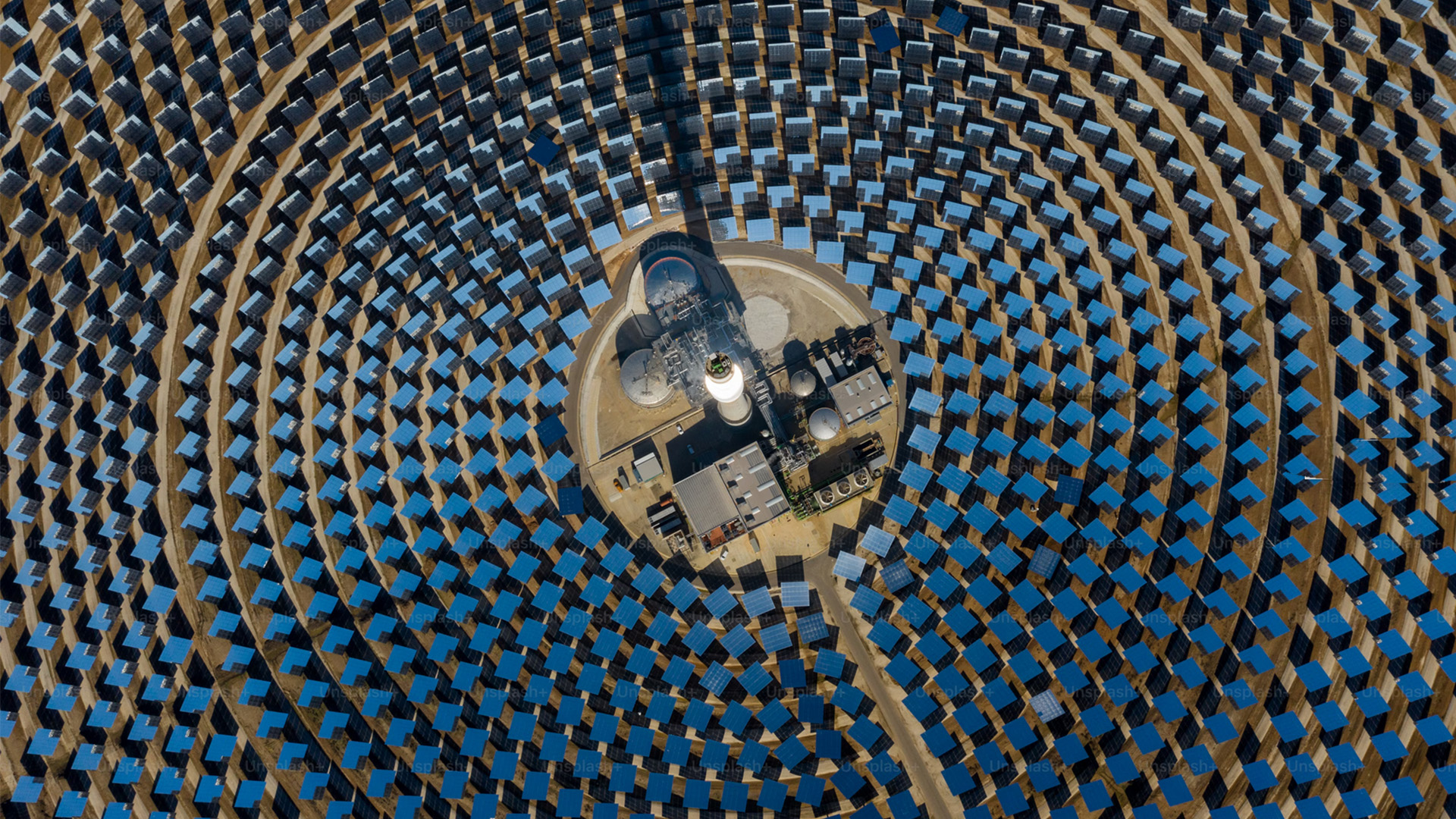

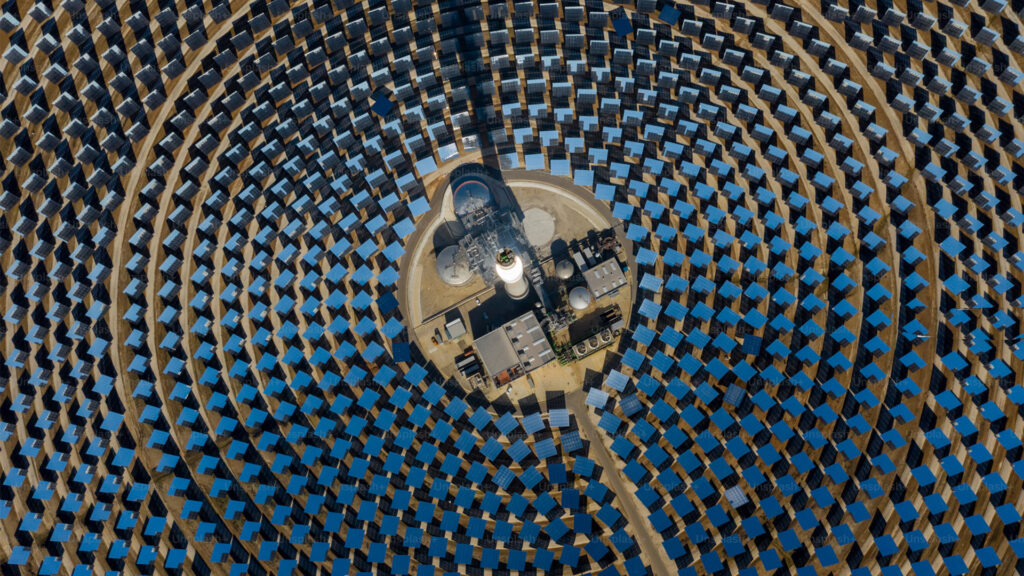

As SRI senior researcher Junhua Austin Wei explained to CompositesWorld, using CMCs in products like solar receivers will require CMCs that are as cheap or cheaper than current metallic solutions: “We have no market if our cost is higher than current nickel alloys.”

SRI’s method, Wei explained to CompositesWorld, is well on its way toward producing CMCs that retain 80% of the performance of standard CMC manufacturing methods at just 50% of current costs.

Read the CompositesWorld article or contact us to learn more about advanced CMC development and manufacturing.